Have you found that maybe most of the sanitary ware in your home is made in China? In our research, we found that most of these products are produced in Foshan, Wenzhou, Chaozhou, Dongguan, Kaiping, and other Chinese regions. While these products have served you well for a long time, there are a few exceptions that have made their way into your home with some flaws.

That’s why when you’re shopping for bathroom products, we recommend that you carefully create your sanitaryware and tap quality inspection checklists. In today’s guide, we will popularize the knowledge related to the quality inspection of Chinese sanitary ware for you. Read on to learn more.

1. What are bathroom products?

Sanitaryware products include items used in bathrooms, toilets, urinals, vanities, sinks, toilets and spas. They include items made of ceramics and related products. Below is a list of everyday hygiene products that should undergo a quality test.

- 1. Bathtub

- 2. Toilet

- 3. Buckets

- 4. Sink

- 5. Washbasin

- 6. Tray

- 7. Soap holder

- 8. Towel Bar

- 9. Ashtray

- 10. Toilet Paper Holder

- 11. Urinals

- 12. Base and other products

(Looking for a reliable bathroom accessories manufacturer? Your request will be met.)

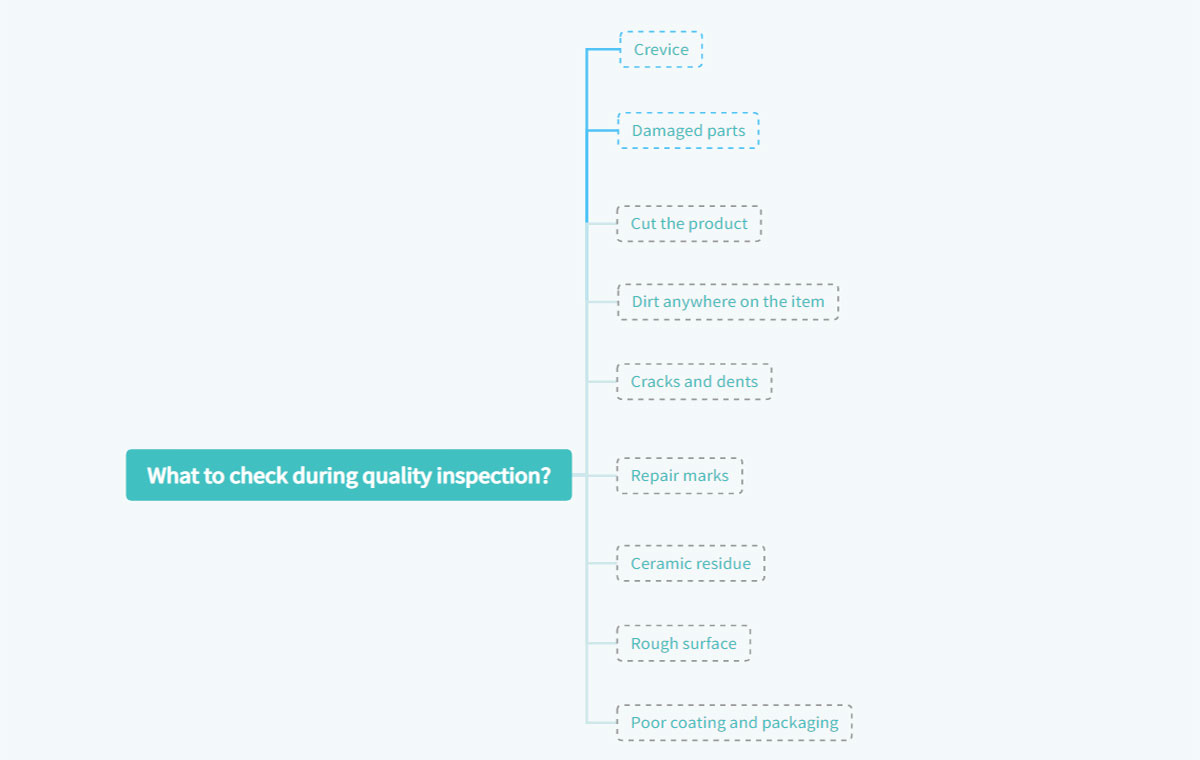

2. What to check during quality inspection?

Quality inspection is a thorough and extensive process. During this process, testers not only check product specifications but also test products to confirm that they can withstand the actual working conditions they will be put into. Below are the details of the inspection you should have on your item.

1) Crevice

When checking for crevices, the main thing is to make sure there are no unnecessary spaces in the product that could make them prone to falling apart, especially items like plinths.

2) Damaged parts

Damaged parts can cause secondary damage to your product. During inspection, the process involves making sure that all parts are intact.

3) Cut the product

Deep or shallow cuts can also leave your items vulnerable to early damage. They can also imply an out-of-proportion mix of manufacturing materials.

4) Dirt anywhere on the item

Dirt may mean that the product has been handled roughly or may have been used before. An inspection can help you rule out any defective items.

5) Cracks and dents

Cracks and dents can also mean that the item may have been used before.

6) Repair marks

This involves checking each product for minor repair marks that could affect its quality.

7) Ceramic residue

Quality products should not have any ceramic residue left on them.

8) Rough surface

These items should also have regular surfaces to help them withstand the elements that can damage them.

9) Poor coating and packaging

Products are inspected here to ensure all items meet the required coating or packaging standards prior to importation.

(Another related post: Bathroom Furniture Buying Guide)

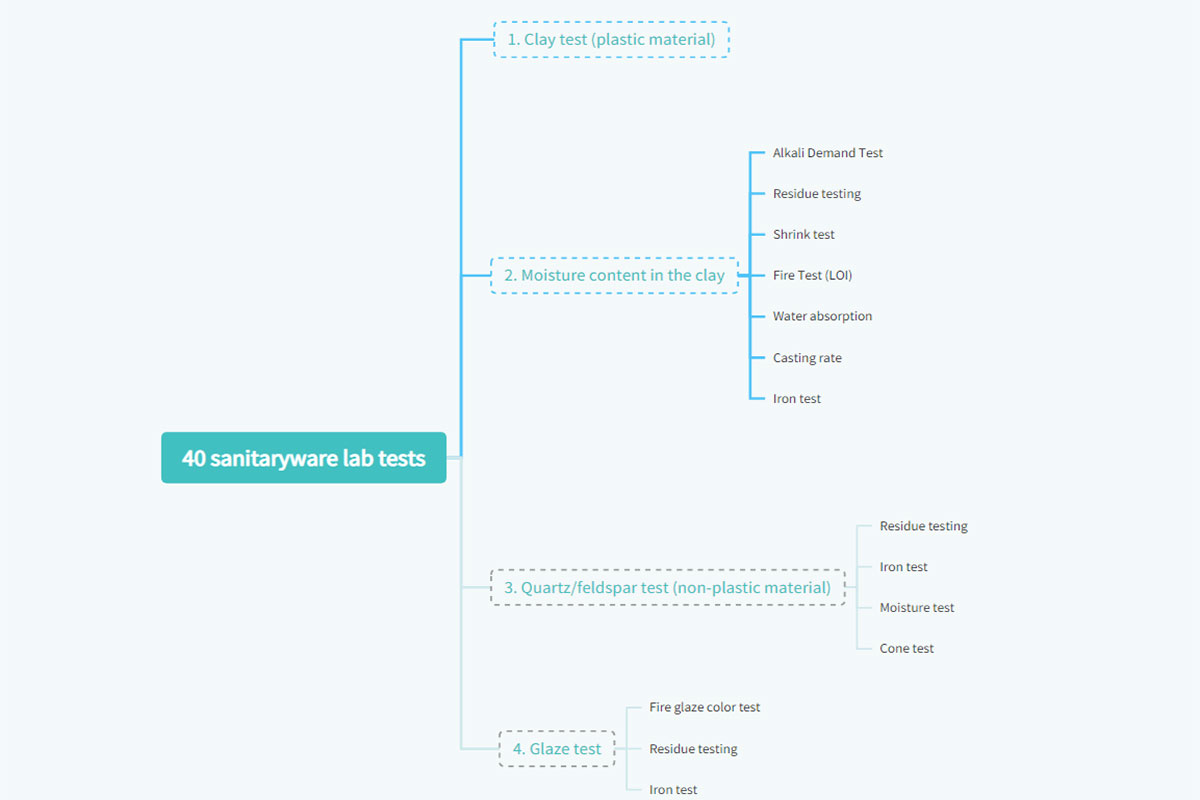

3. 40 sanitaryware lab tests

1. Clay test (plastic material)

2. Moisture content in the clay

-

- Alkali Demand Test

- Residue testing

- Shrink test

- Fire Test (LOI)

- Water absorption

- Casting rate

- Iron test

3. Quartz/feldspar test (non-plastic material)

-

- Residue testing

- Iron test

- Moisture test

- Cone test

4. Glaze test

-

- Fire glaze color test

- Residue testing

- Iron test

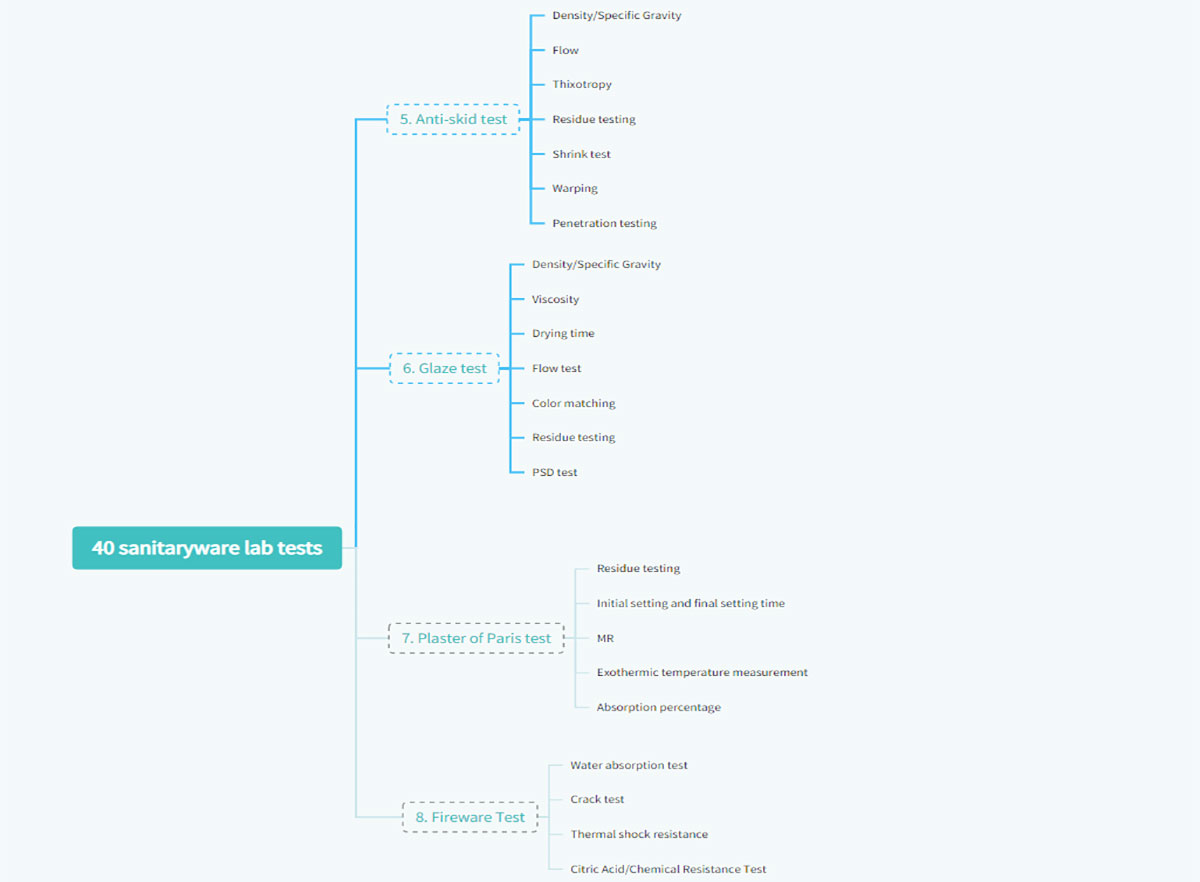

5. Anti-skid test

-

- Density/Specific Gravity

- Flow

- Thixotropy

- Residue testing

- Shrink test

- Warping

- Penetration testing

6. Glaze test

-

- Density/Specific Gravity

- Viscosity

- Drying time

- Flow test

- Color matching

- Residue testing

- PSD test

7. Plaster of Paris test

-

- Residue testing

- Initial setting and final setting time

- MR

- Exothermic temperature measurement

- Absorption percentage

8. Fireware Test

-

- Water absorption test

- Crack test

- Thermal shock resistance

- Citric Acid/Chemical Resistance Test

The above tests are common in sanitary industry laboratories. These tests are to ensure the proper use of your bathroom products. If you want to have your product tested, please contact a professional tester.

(Another related post: How to Start a Kitchen Cabinet Business?)

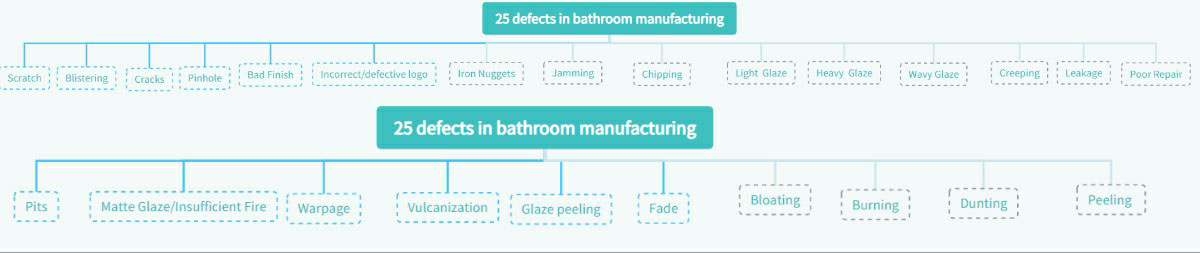

4. 25 defects in bathroom manufacturing

Defects in sanitary ware can affect yield. We list common defects in sanitary ware that can arise from raw materials, handling, or workmanship.

- Scratch – one of the main defects found during the production of sanitary ware. Separation/disintegration of sanitary ware surfaces without cracking.

- Blistering – Blistering is gas bubbles that burst with sharp edges. Can be found in burnt vessels.

- Cracks – Cracks in glazed areas.

- Pinhole – A small hole in a vessel.

- Bad Finish – A product that is found to be incorrectly finished at the green stage after firing.

- Incorrect/defective logo – The logo is not printed or positioned correctly.

- Iron Nuggets – Iron nicks found on glazed surfaces. Defects can be found after firing.

- Jamming – Two or more articles sticking together during firing.

- Chipping —Small splinters on a vessel.

- Light Glaze – The amount of glaze in the vessel is less than necessary.

- Heavy Glaze – More glaze is applied to the vessel than necessary.

- Wavy Glaze – Rippled glazed surface due to improper glazing.

- Creeping – A small portion of the glaze separates from the vessel, leaving the vessel exposed.

- Leakage – Leakage is detected during the filling and rinsing of the vessel.

- Poor Repair – Defects due to poor repair at various stages in the process.

- Pits – small pits found in the glaze after firing.

- Matte Glaze/Insufficient Fire – Improperly fired or matte glaze in the vessel.

- Warpage – product bending.

- Vulcanization – A dull scum that appears on the glaze after firing.

- Glaze peeling – Glaze peeling off during processing.

- Fade – the color disappears after firing.

- Bloating – air bubbles trapped in the body during the shot.

- Burning – Impurities are burned off during the firing process.

- Dunting – Cracks are formed during the silica conversion stage and glaze fills the cracks.

- Peeling – The peeling of the glaze from the body.

(Another related post: A Complete Guide for Buying Bathroom Cabinets)

5. Frequently asked questions

Below are answers to frequently asked questions about bathroom product inspections.

1) Is functional testing important?

Functional testing is important to help you determine that the Chinese product you purchase will perform the desired function and most importantly prevent possible defects during operation. This ensures your smooth use in everyday life. In the functional test of the sanitary ware, some of the following tests were carried out:

- Water leak test.

- Water consumption test.

- Ball (flush) test.

- surface cleaning tests, and

- Leakage/vacuum test etc.

2) Is the defect of sanitary ware easy to appear?

Sanitary ware in the production process may produce the above-mentioned defects, but the probability of defects is not high, generally only a few percent. However, when you buy the product, it is best to check whether the product has the above defects to avoid buying bad products.

(Another related post: Bathroom Accessories: A Full Guide)

6. Conclusion

This guide mainly introduces you what is bathroom products and some testing standards for bathroom product inspection. This knowledge is very helpful for you when purchasing bathroom products. If you have other questions, please contact Nicemoco.

How useful was this post?

Click on a star to rate it!

Average rating 5 / 5. Vote count: 3

No votes so far! Be the first to rate this post.